Brooks are the world's leading authority on the manufacture and supply of high performance pin oven chains to the Beverage Can Industry. Complimenting the chains is a range ofprecision sprockets for the oven, pre-dry and chain return, single sided chain guide,electrostatic lubricators, bull gears, inker gears and anti-backlash gears.

Efficient oven pin chain

Brooks Provide three types of oven pin chains

1. Hollow pin oven chain:

Lock nuts developed to aerospace industry standards secure the pins in the chain yet allowquick and easy replacement whenever necessary

2. Front fixing pin oven chain:

Similar to the hollow pin chain, this design alsoallows for easy replacement of the can carryingpin. With this design the pins are secured usingcotter pins on the same side as the extended pinmaking this chain ideal for encapsulated chainguide systems.

3. Dual pin oven chain:

Specially designed to suit dual can transfer unitsgiving the benefit of doubling can production forany given chain speed. Chains are assembledwith small diameter tips to aid can transfer anda central cone to aid can stability.

4. Special hollow pin:

Brooks can offer any pin spacing to suit allcustomer requirements.

Pin and pin rubber head

We provide four kinds of standard pin rubber heads for pins of any length:

PEEK tip can withstand high temperature of 350 ℃.

1. Integral pin oven chain

2. Optima pin oven chain

3. Lube free pin oven chain

Precision Gears

Brooks can provide precisiongears to suit all two-pieceand three-piece applications.including print cylinder gearsinker gears, bull gears andanti-backlash gears.

Precision Sprockets

Brooks manufacture sprocketsfrom certified ground plate andstrict tolerances are appliedto flatness, concentricity.tooth profile and pitch. Toothhardness is achieved by 'toothby tooth' induction hardeningor tooth *flame hardening'

Adjustable Chain Guides

Installed on alternate sides ofvertical runs and above andbelow on horizontal runs, Brookssingle sided chain guides aredesigned to reduce chain and cancontamination. They are easy toinstall, easy to maintain, easyto adjust and easy to clean.

PLC lubrication control system

To maximise pin chain life a good qualitylubricant must penetrate the chain to forma barrier between the chain bearing pin andbush.

Brooks Engineering Team

Brooks has trained a group of professional engineers with many years of on-site experience to travel around the world and renovate the oven into a standard setting suitable for the requirements of modern high-speed lines.

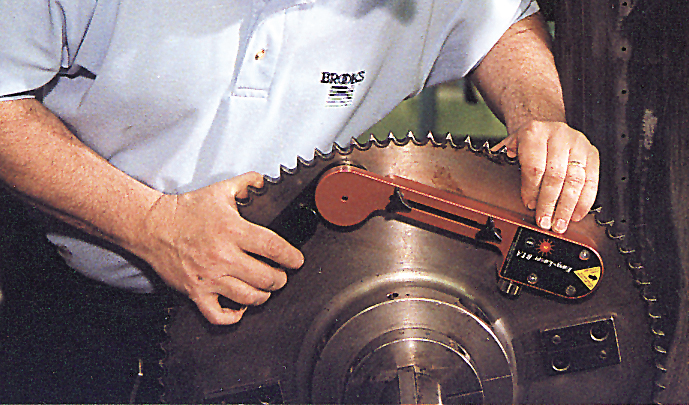

With the laser detector, BROOKS also provides on-site chain wheel alignment and calibration services to help customers extend the service life of the chain.

Brooks provides training on the maintenance of Brooks products for engineers on the production line.

Pin chain specification

1、Length:Chain manufactured in 21ft lengths (6.4m, 336 x 0.75 pitches)

2、Weight: 1.47 kg/m

3、Tensile Strength: 7492 lbs min

4、Material: steel

5、Type: 34" pitch ASA60 simplex chain, fully assembled with an

PIN

The chain pin is a key component in the pin chain, which is the transmission component in the oven. High temperature resistance, not easy to bend and other characteristics are required;

The length can be determined according to the customer's requirements.

Net weight of each pin: 0.082 kg;

For further details, please visit the Brooks website: www.brooks.ltd.uk